When deciding between plastic and silicone molds, several differences may guide your choice. Plastic molds are generally more affordable but tend to be less durable over time. They can crack or warp, especially with frequent use. This makes them a budget-friendly choice for simple or one-time projects.

On the other hand, silicone molds offer flexibility and longevity. Silicone is resilient under pressure, which helps these molds last longer without losing their shape. This makes silicone ideal for projects where you need to craft unique shapes with custom silicone molds.

Choosing between these two materials depends on your project needs and budget. Whether you’re looking for durability or cost-effectiveness, understanding these key differences will help you decide which mold best suits your crafting endeavors.

Composition and Properties

Plastic and silicone molds differ in their materials, chemical makeup, heat tolerance, and physical properties. Understanding these differences can help you decide which type is suitable for your needs, whether you require high durability or specific thermal capabilities.

Materials Used

Silicone molds are typically made from a combination of silicon, oxygen, and other elements, resulting in a flexible material. Silicone is often free from harmful chemicals and suited for various applications, including food-grade uses.

In contrast, plastic molds are primarily composed of polymers such as polyethylene or polycarbonate. These materials offer a wide variety of applications depending on the additives used, making them ideal for specific industrial tasks but less suitable for heat-sensitive applications.

Chemical Structure

Silicone has a backbone of silicon and oxygen, contributing to its flexibility and resistance to environmental changes. This structure lends silicone its ability to stretch and compress without losing form and also improves its resilience to heat and chemicals.

Plastic typically consists of a carbon and hydrogen backbone. This makes plastic materials more rigid and durable but less suited to extreme temperature shifts. Plastics can be further modified through chemical additives to achieve specific properties like increased hardness or flexibility.

Thermal Characteristics

Silicone is known for its high heat resistance, typically able to withstand temperatures ranging from -60°C to 230°C. This makes it suitable for both freezing and baking applications, retaining its shape and properties under different conditions.

Plastic molds have a narrower temperature tolerance. They are often more prone to warping or deformation when exposed to heat beyond their specific temperature range. Many types of plastic are not recommended for use in high-temperature applications due to these limitations.

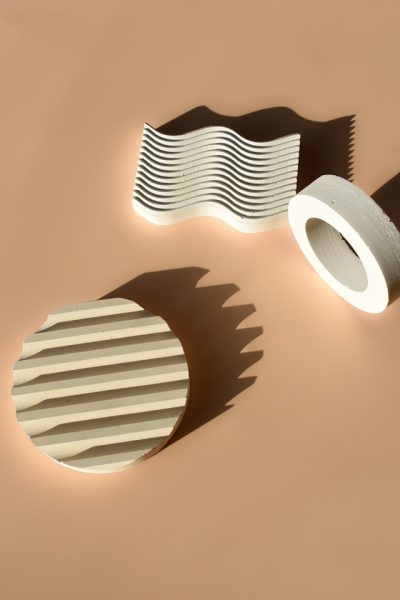

Durability and Flexibility

Silicone molds offer superior flexibility, allowing easy release of molded items without damaging the mold itself. This flexibility also makes silicone resistant to cracks and other physical wear, providing a longer useful life in applications requiring frequent use.

Plastic molds, while generally more rigid, offer greater durability in situations not involving extreme temperatures. They are ideal for applications where dimensional stability and hardness are necessary. However, their rigidity can limit their ability to adapt to frequent stress or bending.

Applications and Usability

When choosing between plastic and silicone molds, consider their uses, ease of release, and cleaning requirements. Silicone’s flexibility plays a significant role in various applications, while plastic is valued for its firmness and precision.

Suitability for Different Uses

Plastic and silicone molds serve different purposes based on their material characteristics. Silicone molds are great for baking and candy making. Their flexibility helps in easily releasing items like cakes and candies without breaking them. They’re also suitable for crafting, such as soap or candle making, because they handle heat well.

On the other hand, plastic molds are sturdier and maintain their shape, making them ideal for projects requiring precision and detailed designs. They are often used in chocolate making and certain types of crafting where intricate details are needed. Silicone molds may not match the fine details achievable with plastic molds due to their softer nature. If you need molds for baking or crafting, consider what characteristics are most important for your specific use.

Ease of Maintenance

Cleaning and maintaining molds affect their long-term usability. Silicone molds are generally easy to clean because they resist stains and odors. They are often dishwasher safe, which simplifies the cleaning process. Due to their non-stick surface, less effort is needed to remove residues. This makes them a popular choice for frequent users.

Plastic molds, while sturdy, may require more care during cleaning. They can sometimes harbor stains or odors if not washed thoroughly. Most plastic molds need to be hand-washed to avoid deformation or damage. Carefully drying them after washing is important to prevent any watermarks or spotting.

Conclusion

When choosing between plastic and silicone molds, it’s important to consider their strengths and weaknesses. Silicone molds are flexible, easy to use, and resist high temperatures. This makes them great for projects like baking and candy making.

Plastic molds are generally less expensive and are good for simpler uses. However, they may not last as long, especially if they are regularly exposed to heat or pressure. Plastic molds might also hold their shape better for certain applications.

Ultimately, the right mold for you will depend on what you’re making and how you plan to use it. Each type offers unique benefits, so weigh the factors that matter most to your needs.